600X-Electric control valve

- Commodity name: 600X-Electric control valve

- Product description

-

PRODUCT INTRODUCTION

600X hydraulic electric control valve is used for water supply, air conditioning, and fire protection pipeline systems. The medium is water, with a temperature of ≤ 80 ℃. Using an solenoid valve as a pilot valve, when the solenoid valve is powered on or off, the valve is controlled to open and close by the pressure of water in the pipeline.

It consists of main valve, solenoid valve, needle valve, ball valve and other components. Simultaneously, the control circuit requires a liquid level switch. Or components such as electric contact pressure gauges can be used to achieve interlocking control.

WORKING PRINCIPLE

The medium at the inlet end of the valve runs along the conduit. Needle valve. Enter the upper chamber of the diaphragm. When the solenoid valve coil is energized, the solenoid valve opens. The medium in the upper chamber of the main valve diaphragm flows along the solenoid valve and ball valve to the outlet, and the pressure in the upper chamber of the diaphragm decreases. Under the pressure difference, the medium pressure pushes open the main valve core, the main valve opens, and water supply begins. When the solenoid valve coil is powered off, the solenoid valve remains closed, and the outflow channel on the main valve diaphragm remains closed. Due to the larger membrane area than the main valve core area, the main valve closes under the pressure difference between the two. When used for pool level control: When the level drops to the set low level, the level switch sends a signal, the solenoid valve coil is energized, the solenoid valve opens, and then the main valve opens to start supplying water. When the liquid level in the pool reaches the set height value, under the action of the liquid level switch, a control signal is issued, and the solenoid valve is closed, thereby closing the main valve and stopping the water supply. This reciprocating cycle keeps the water level in the pool stable within a certain range. Its principle is similar to that of a 100X remote-controlled float valve, except that an electromagnetic valve is used instead of a small float valve. However, the 100X remote control float valve achieves liquid level feedback and control functions through a small float valve. Simpler and more practical, without the need for wiring, purely mechanical control. The 600X hydraulic electric control valve only has control functions and requires liquid level detection instruments to be used in conjunction. When using an electric contact pressure gauge, the pipeline pressure can also be controlled. Wider application.

MAIN TECHNICAL PARAMETERS

Nominal pressure Mpa Shell Test Pressure Mpa Sealing test pressure Mpa Using media Medium temperature 1.0 1.5 1.1 Water 80℃ 1.6 2.4 1.76 Water 80℃ 2.5 3.75 2.75 Water 80℃ INSTALLATION AND ADJUSTMENT

1. When the solenoid valve starts, the main valve opens. When the solenoid valve is closed, the main valve is closed. The voltage of solenoid valves is commonly used as AC 220V or DC 24V, normally closed. When the solenoid valve coil is damaged. The solenoid valve can be closed. Then the main valve remains closed. Electromagnetic valves can also be normally open, with the main valve remaining normally open. Select the normally open and normally closed states of the solenoid valve according to process requirements and safety.

2. The needle valve on the catheter can adjust the closing time of the main valve. Closing the needle valve in a timely manner can prolong the closing time of the main valve core, achieve a slow closing effect, and reduce water hammer phenomenon. Increasing the opening of the needle valve counterclockwise will accelerate the closing time of the main valve.

3. The ball valve on the conduit serves to emergency close the main valve. When the solenoid valve fails and cannot be closed, the ball valve can be manually closed. The outlet of the valve chamber on the disc is closed, the pressure increases, and then the main valve closes.

4. A filter should be installed in front of the main valve to prevent impurities from blocking the conduit, needle valve, and solenoid valve. Impurities can also cause the main valve core to not close tightly, causing the water level in the pool to be too high and causing overflow.

INSTALLATION DIAGRAM

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

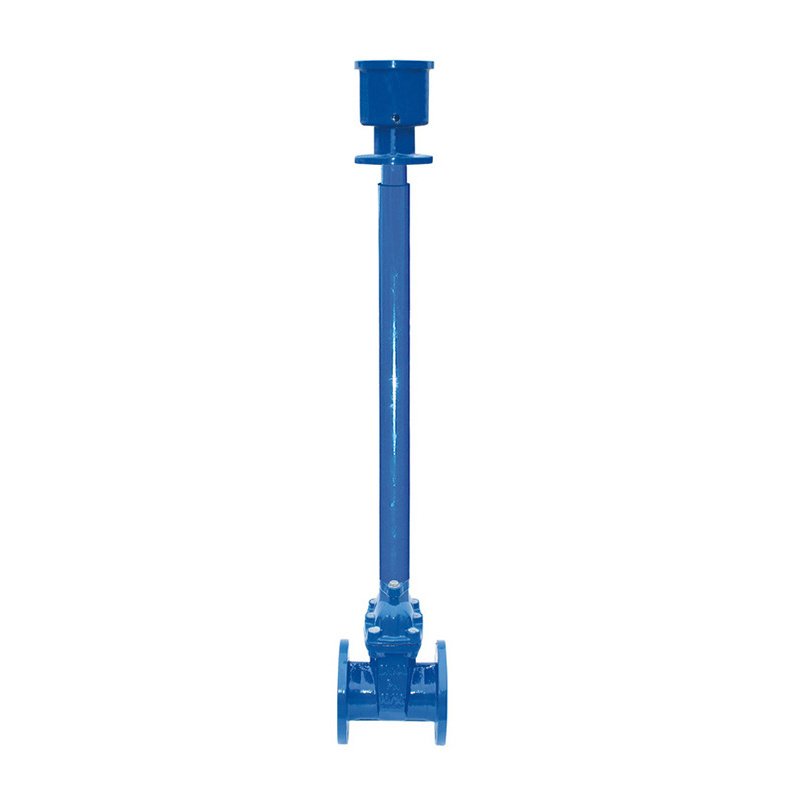

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.