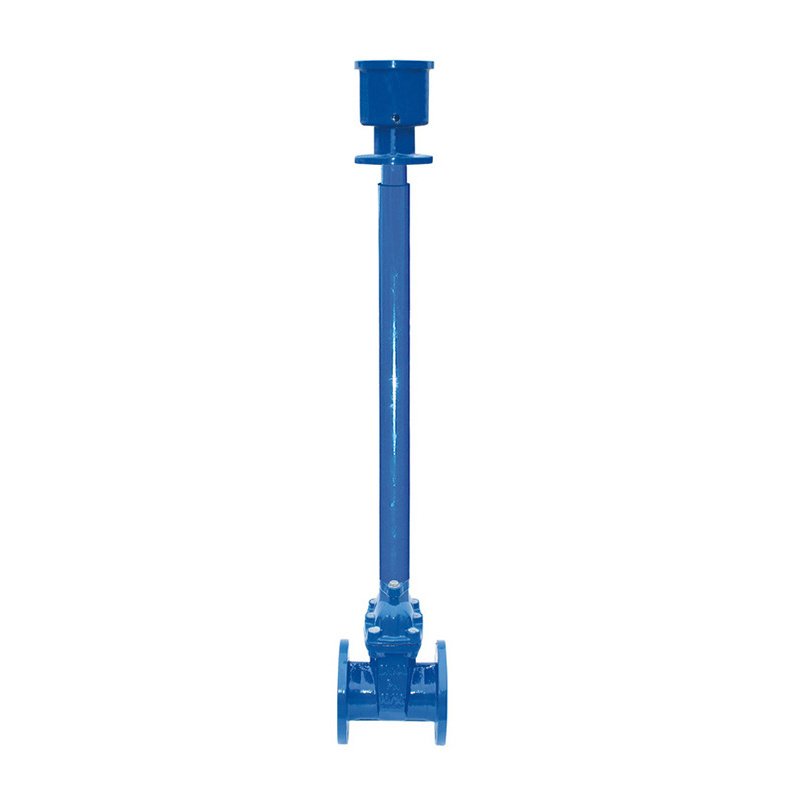

Bevel gear soft seal gate valve with BS5163 and DIN3352 F4

- Commodity name: Bevel gear soft seal gate valve with BS5163 and DIN3352 F4

- Product description

-

INTRODUCTION TO GERMAN STANDARD F4 SOFT SEAL GATE VALVE

The German standard F4 concealed rod soft sealed elastic gate valve is suitable for liquid and gas medium pipelines and equipment, serving as a cut-off medium.

Elastic soft seal gate valve utilizes the movement direction of the elastic gate to be perpendicular to the direction of the fluid, so the soft seal gate can only be fully open and fully closed, and cannot be used for adjustment or throttling. The soft sealed gate valve utilizes the deformation compensation effect generated by the overall encapsulation of the gate to achieve a good sealing effect, overcoming the phenomena of poor sealing, water leakage, and rust in general gate plates. This gate valve has the characteristics of fast installation, easy maintenance, long service life, and less prone to water hammer.

The bottom of the elastic soft seal gate valve adopts the same flat bottom design as the water pipe, which is not easy to cause debris accumulation and allows the fluid to flow unobstructed.

The handwheel is closed clockwise and open counterclockwise, and no leverage is allowed.PERFORMANCE CHARACTERISTICS OF GERMAN STANDARD F4 SOFT SEAL GATE VALVE

1. Not easy to break, traditional cast iron soft seal gate valves used to be prone to breakage due to external objects hitting, colliding, or overlapping. Due to the use of ductile iron for soft sealed gate valves, this situation can be significantly reduced.

2. Corrosion resistant, soft sealed gate valve body is coated with powder epoxy resin to prevent corrosion and rust of the valve body, and can be used in sewage systems.

3. The overall rubber coating and soft sealing gate valve plate are made of high-quality rubber for internal and external sealing. The first-class rubber vulcanization technology in China ensures accurate geometric dimensions of the vulcanized valve plate, and the rubber is firmly connected to the ductile iron gate plate, which is not easy to fall off and has good elastic memory.

4. Flat bottomed valve seat, traditional gate valves often accumulate in the valve bottom groove due to external objects such as stones, wooden blocks, cement, paper scraps, debris, etc. after washing the pipe with water. It is easy to cause leakage due to the inability to close tightly. The lower part of the soft sealed gate valve adopts the same flat bottom design as the water pipe, which is not easy to cause debris accumulation and makes the fluid unobstructed.

5. Three "O" - shaped sealing rings, as the valve stem adopts a three "O" - shaped sealing ring design. It can reduce the frictional resistance during switching, significantly reduce water leakage, and replace the sealing ring during uninterrupted water construction.

6. Helpful for drinking, due to the non-toxic epoxy resin coating inside the valve body, the inner and outer surfaces of the gate valve are completely covered with rubber without rust or corrosion, making it suitable for drinking.

7. Precision cast valve body, the valve body adopts precision casting, and the precise geometric dimensions ensure the sealing of the valve without any precision machining inside the valve body.

8. Lightweight, the body is made of ductile iron casting, which reduces the weight by about 20% to 30% compared to traditional gate valves, making it convenient for maintenance.

CHARACTERISTICS OF SOFT SEAL GATE VALVES

1. Low flow resistance. The medium channel inside the valve body is straight, and the medium flows in a straight line with low flow resistance.

2. It is more effortless to open and close. Compared to globe valves, the direction of gate movement is perpendicular to the direction of medium flow, whether it is open or closed.

3. High height, long opening and closing time. The opening and closing stroke of the gate is relatively large, and the lowering is carried out through the screw.

4. The phenomenon of water hammer is not easy to occur. The reason is that the shutdown time is long.

5. The medium can flow in any direction on both sides, making it easy to install. The two sides of the gate valve channel are symmetrical.

6. The structural length (the distance between the two connecting end faces of the shell) is relatively small.

7. Simple shape, short structural length, good manufacturing process, and wide applicability.

PART MATERIAL

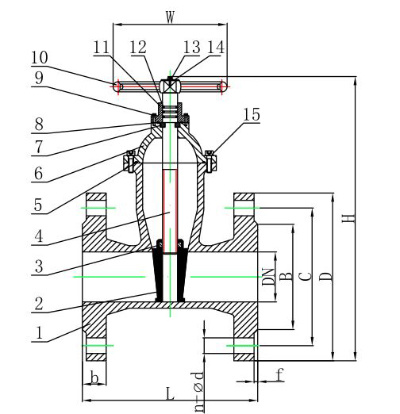

Part Name Material Valve body and valve cover Nodular cast iron Ram Nodular cast iron+EPDM Valve stem Stainless steel Stem nut Brass Filler EPDM Hexagonal socket nut Carbon steel Shim EPDM MAIN TECHNICAL PARAMETERS

◆ Nominal pressure: 1.0-1.6 MPa

◆ Nominal diameter: 40-1200mm

◆ Working temperature: 0-80 ℃

◆ Flange standard: EN1092-2 PN10/PN16

◆ Test standards: EN1074-1 and 2/EN12266

Nominal size DN40~DN1200 Applicable Medium Clear water or a medium with physical and chemical properties similar to water

(Please specify sewage, raw water, hot water, and oil media)Operation temperature ℃ 0-70 (Standard configuration) 0-100 (Hot water configuration) Nominal pressure PN10 PN16 Working pressure(MPa) ≤1.00 ≤1.60 Strength test(MPa) 1.50 2.40 Sealing test(MPa) 1.10 1.76 ◆ Applicable media: Clear water or media with physical and chemical properties similar to water

◆ Drive mode: manual

◆ Compliant with standards: DIN3352 F4, EN1171

Size L D C B n-d b f H DN50 150 165 125 99 4-19 19 3 280 DN65 170 185 145 119 4-19 19 3 305 DN80 180 200 160 133 4-19 8-19 19 3 350 DN100 190 220 180 154 8-19 19 3 390 DN125 200 250 210 184 8-19 19 3 470 DN150 210 285 240 210 8-23 19 3 525 DN200 230 340 295 265 8-23 12-23 20 3 630 DN250 250 405 350 355 319 12-23 12-28 22 3 780 DN300 270 460 400 410 370 12-23 12-28 24.5 4 870 DN350 290 520 460 470 429 16-23 16-28 26.5 4 1100 DN400 310 565 580 515 525 480 16-28 16-32 28 4 1200 DN450 330 640 565 585 548 20-28 20-32 30 4 1300 DN500 350 670 715 620 650 582 20-28 20-32 31.5 5 1450 DN600 390 780 840 725 770 682 20-31 20-37 36 5 1650 DN700-DN1200 or above, please contact us for details

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.