Y-Filter

- Commodity name: Y-Filter

- Product description

-

PRODUCT INTRODUCTION

Y-shaped filters are an indispensable device in the pipeline series for conveying media. They are usually installed at the inlet end of pressure reducing valves, relief valves, constant water level valves, or other equipment to eliminate impurities in the medium and protect the normal use of valves and equipment. This filter has the characteristics of advanced structure, low resistance, and convenient discharge. The applicable media can be water, oil, or gas. Filter screens can be made according to user requirements, with a similar appearance (Y-shaped) and all internal components made of stainless steel, which is sturdy and durable. When cleaning is required, simply remove the detachable filter cartridge, remove any impurities filtered out, and reinstall it, making it extremely convenient to use and maintain. This filter has a small body shape, fine filter eyes, low resistance, high efficiency, convenient installation and maintenance, low cost, and short discharge time. For general small-sized filters, it only takes 5-10 minutes.

PRODUCT PRINCIPLE

1. Y-shaped filter is an indispensable filtering device in pipeline systems for conveying fluid media.

2. Y-shaped filters are usually installed at the inlet of pressure reducing valves, relief valves, shut-off valves (such as the inlet end of indoor heating pipelines) or other equipment to remove impurities in the medium and protect the normal use of valves and equipment.

3. The Y-shaped filter has an advanced structure, low resistance, and convenient drainage.

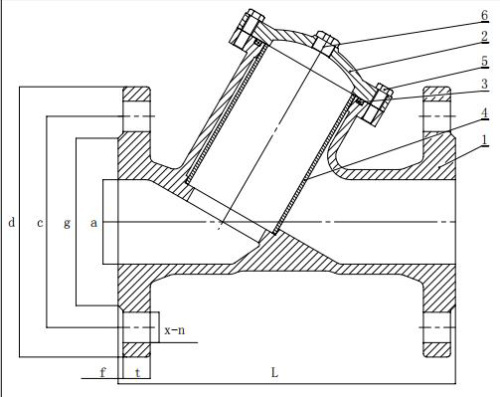

4. The Y-shaped filter mainly consists of a connecting pipe, a main pipe, a filter screen, a flange, a flange cover, and fasteners. When the liquid enters the filter basket through the main pipe, solid impurity particles are blocked in the filter basket, and clean fluid is discharged through the filter basket and the filter outlet. The reason why the filter screen is made into a cylindrical filter basket shape is to increase its strength, which is more sturdy than a single-layer mesh. The flange cover at the lower end of the Y-shaped interface can be unscrewed to regularly remove particulate impurities deposited in the filter basket.

PRODUCT USAGE PRECAUTIONS

After the initial operation of the system for a period of time (usually no more than a week), cleaning should be carried out to remove impurities and dirt accumulated on the filter screen during the initial operation of the system. Afterwards, regular cleaning is required. The cleaning frequency depends on the operating conditions. If the filter is not equipped with a drain plug, the filter limiter and filter should be removed when cleaning the filter.

1. Before each maintenance and cleaning, the filter should be isolated from the pressurized system. After cleaning, use a new sealing gasket when reinstalling.

2. Before installing the filter, carefully clean the threaded connection surfaces of all pipelines, and use appropriate amounts of pipeline sealant or PTFE tape (polytetrafluoroethylene). Do not treat the end threads to prevent sealant or PTFE tape from entering the piping system. The filter can be installed horizontally or vertically downwards. When installing socket welding filters with a diameter of 1-1/4 "(DN32) or larger, or all D-series filters, it should be noted that the gasket of these filters is made of non-metallic material, which is prone to damage due to overheating. Therefore, the welding time should be shortened and the filter should be cooled after welding is completed. If preheating is required before welding or further heating is required after welding (D-series filter), it is recommended to remove the gasket before heating.

3. A Y-shaped filter is a small device that removes small amounts of solid particles from liquids, which can protect the normal operation of the equipment. When the fluid enters the filter cartridge with a certain specification of filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is needed, simply remove the detachable filter cartridge, process it, and reinstall it. Therefore, maintenance is extremely convenient.

PRODUCT PARAMETERS

DN L a d c x-n t f g 50 230 50 165 125 4-Φ19 19 2 99 65 290 65 185 145 4-Φ19 19 2 118 80 310 80 200 160 8-Φ19 19 3 132 100 350 100 220 180 8-Φ19 19 3 156 125 400 125 250 210 8-Φ19 19 3 184 150 480 150 285 240 8-Φ19 19 3 211 200 600 200 340 295 12-Φ19 20 3 266 250 730 250 405 355 12-Φ19 22 3 319 300 850 300 460 410 12-Φ19 25 4 370 350 980 350 520 470 16-Φ19 26.5 4 429 400 1100 400 580 525 16-Φ19 28 4 480 450 1200 450 640 585 20-Φ19 30 4 548 500 1250 500 715 650 20-Φ19 32 4 609 600 1450 600 840 770 20-Φ19 36 5 720

NO. Name Part Material 1 Body Ductile Iron 2 Cap Ductile Iron 3 Sealling EPDM 4 Fliter cscreen SS304 5 Nut SS201 6 Ventplug SS201

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

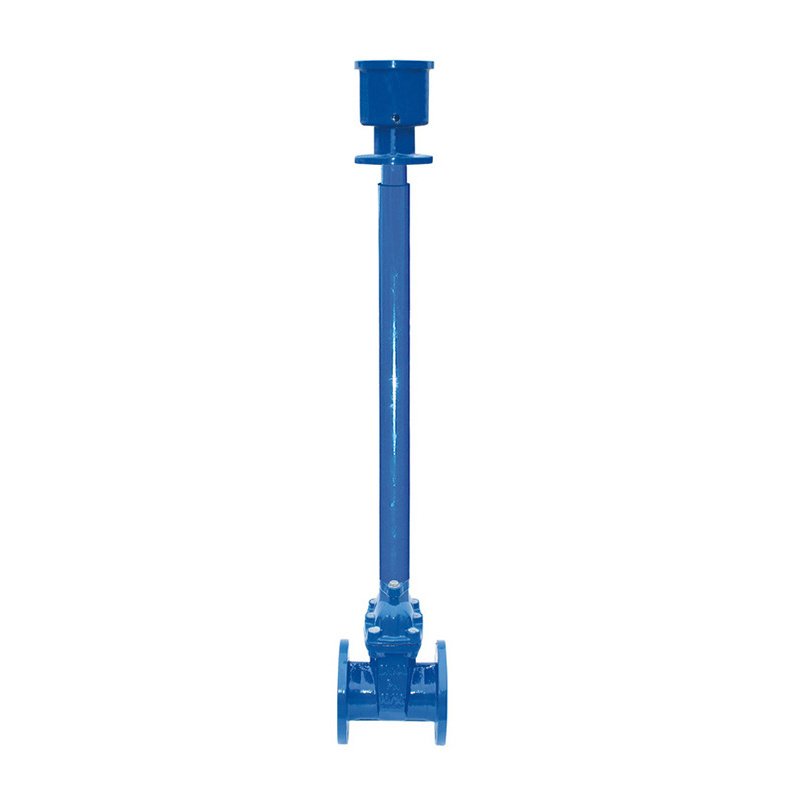

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.