800X-Differential pressure bypass valve

- Commodity name: 800X-Differential pressure bypass valve

- Product description

-

PRODUCT INTRODUCTION

The 800X differential pressure bypass valve, also known as the electric differential pressure bypass valve, is a valve used to balance the pressure difference between the supply and return water of air conditioning systems. This valve can improve the utilization rate of the system, maintain precise alignment of pressure differences, and minimize system noise and equipment damage caused by excessive pressure differences.

WORKING PRINCIPLE

The 800X differential pressure bypass valve consists of a hydraulic control connecting system consisting of a main valve, differential pressure control pilot valve, needle valve, ball valve, micro filter, and pressure gauge. Through a specially designed pilot valve control room, the pressure change signal is compared, and the main valve opening signal is output to control the main valve opening, thereby controlling the inlet and outlet pressure difference of the main valve at the set value.

When the pressure difference between the inlet and outlet of the main valve changes, the pressure difference between connecting pipe A and connecting pipe B changes, which affects the opening of the pilot valve. When the pressure difference is large, the opening of the pilot valve is large, and the amount of water discharged through pipe C in the control room increases. The pressure in the control room of the main valve decreases, and the opening of the main valve increases. The pressure difference between the inlet and outlet of the main valve decreases. On the contrary, if the pressure difference between the inlet and outlet of the main valve decreases, the opening of the pilot valve decreases, and the pressure in the control room of the main valve increases, pushing the opening of the main valve to decrease and causing the pressure difference of the main valve to increase. This negative feedback effect stabilizes the pressure difference between the inlet and outlet of the main valve at the peak value. The opening of the needle valve and the pressure of the guide valve spring can be used to set the pressure difference between the inlet and outlet of the main valve.

TECHNICAL PARAMETERS

Nominal diameter: DN50-DN600

Nominal pressure: PN10/16

Working temperature: 0 ℃ -80 ℃

Applicable medium: water

INSTALLATION INSTRUCTIONS

1. Loading and unloading: The 800X differential pressure bypass valve should be carefully loaded and unloaded. It is recommended to use soft ropes to lift it to avoid damaging the valve and piping, protecting the coating layer. The valve should be carefully placed underground and not directly on the ground.

2. Pre installation inspection: After loading and unloading to the destination, first check and confirm according to the instructions provided by ACOL, whether the piping is correct, whether the connection is reliable, whether there is any damage to the valve during transportation, and whether all parts are complete.

3. Before installing the bypass valve, impurities in the pipeline should be cleaned, and the corresponding flange should be checked to ensure that the pressure rating and nominal diameter of the valve flange are consistent, in order to maintain the smoothness of the pipeline.

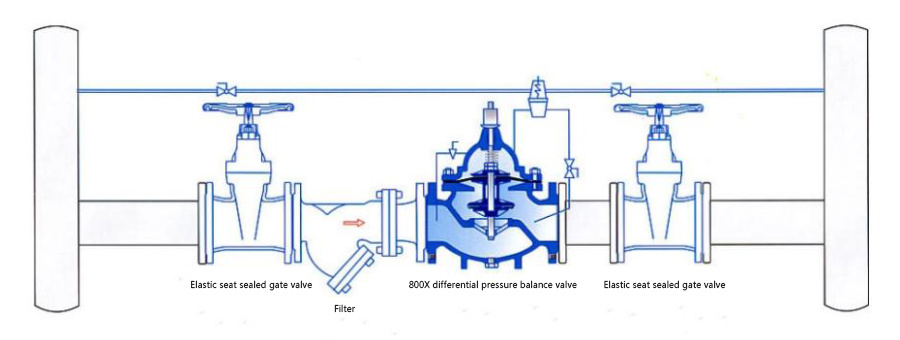

4. Two gate valves should be installed before and after the differential pressure bypass valve for inspection and maintenance purposes.

5. The pipeline for sensing pressure of the differential pressure guide valve should be directly connected to the water supply and return pipelines to accurately reflect the pressure difference between the supply and return pipelines. For the convenience of installation and use, a small ball valve can be installed on the sensing pipeline.

6. There are two pressure connection ports on the differential pressure guide valve, with the upper port connected to the return water pipeline and the lower port connected to the water supply pipeline.

INSTRUCTIONS

1. Before use, check whether all gate valves, ball valves, and needle valves are in a fully open state;

2. Observe the pressure between the supply and return water, adjust the pressure difference guide valve according to the pressure difference, unscrew the top cap on the guide valve, and use a suitable wrench to rotate the top screw. From top to bottom, when rotating clockwise, the pressure difference increases, and when rotating counterclockwise, the pressure difference decreases. Rotate according to the required pressure difference. When the pressure difference reaches the desired value, tighten the top cap, and the pressure difference will be ensured to be within the set pressure difference.

3. The action speed of the main valve can be adjusted by the needle valve. When rotating clockwise, the action slows down, and when rotating counterclockwise, the action accelerates.

NOTE

1. 800X differential pressure bypass valve should not be used on pipelines with a pressure higher than the nominal pressure.

2. Do not use the 800X differential pressure bypass valve on other unsuitable recommended media.

3. Do not expose the 800X differential pressure bypass valve to freezing temperatures.

4. The 800X differential pressure bypass valve cannot be applied outside the range recommended by ACOL.

INSTALLATION DIAGRAM

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.