H300X-Slow closed check valve

- Commodity name: H300X-Slow closed check valve

- Product description

-

PRODUCT OVERVIEW

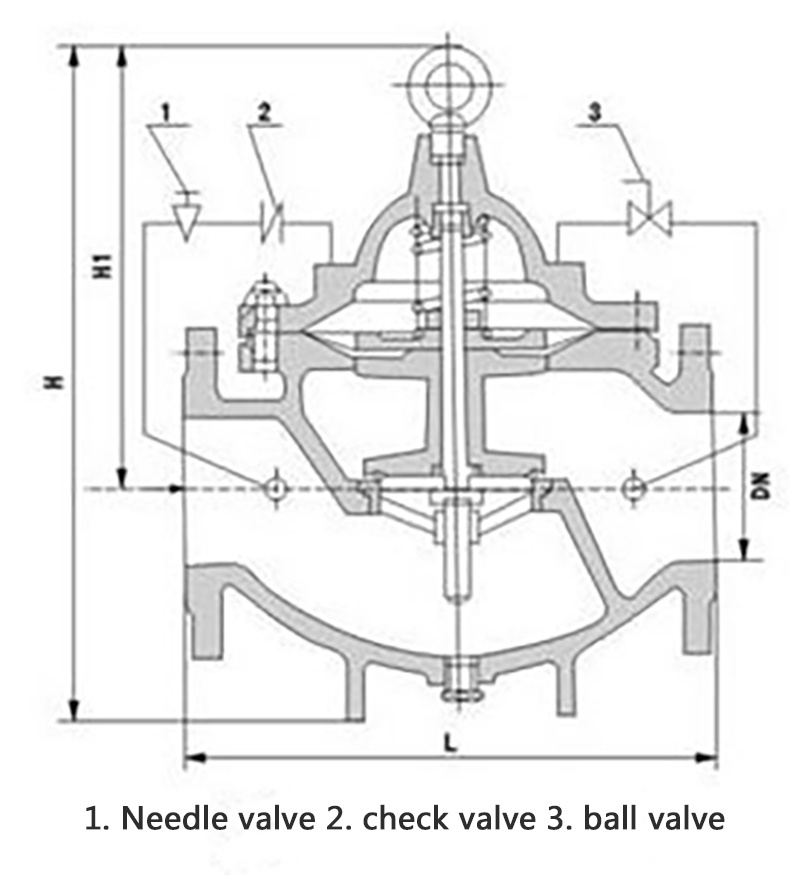

The H300X slow closing check valve consists of a hydraulic control connecting system consisting of a main valve, one-way valve, needle valve, ball valve, etc. By utilizing hydraulic automatic operation, the main valve can achieve the optimal opening or closing speed. To prevent the occurrence of water hammer and achieve the effect of slow closing and noise reduction, this valve is controlled by hydraulic force and does not require other devices or energy. The product is widely used in water supply network systems such as high-rise buildings and residential areas, as well as urban water supply projects.

PRODUCT FEATURES

1. The valve consists of a main valve, a one-way valve, a needle valve, a ball valve, a pressure gauge, etc. As one-way valves, needle valves, pressure gauges, etc. need to be connected to the main valve through pipes, they are collectively referred to as a conduit control system.

2. The valve is controlled by hydraulic self force and does not require other devices or energy. It is easy to maintain and has smooth opening and slow closing.

3. The valve body adopts a full channel and streamlined design, with low fluid resistance and high flow rate.

WORKING PRINCIPLE

When the valve supplies water from the inlet end, the water enters the main valve control room through the needle valve one-way valve, and then flows through the valve guide pipe to discharge downstream. Due to the small opening of the needle valve, i.e. the drainage speed of the main valve control room is greater than the inlet speed, the pressure in the control room decreases. The inlet pressure acting on the lower end of the main valve disc opens the main valve to supply water downstream.

When the pipeline stops supplying water, if the downstream water begins to flow back, a portion of the return water enters the main valve control room through the guide pipe. Due to the action of the one-way valve, the return water cannot flow out of the main valve control room, causing the main valve control room to gradually increase pressure and slowly close the main valve.

MAIN TECHNICAL PARAMETERS

Nominal pressure PN 1.0MPa 1.6MPa 2.5MPa Shell experimental pressure 1.5MPa 2.4MPa 3.75MPa Sealing test pressure 1.1MPa 1.76MPa 2.75MPa Maximum inlet pressure 1.0MPa 1.6MPa 2.5MPa Adjustable range of outlet pressure 0.09-0.8MPa 0.10-1.2MPa 0.15-1.6MPa Temperature 0℃-80℃ Applicable Medium Water INSTALLATION AND ADJUSTMENT

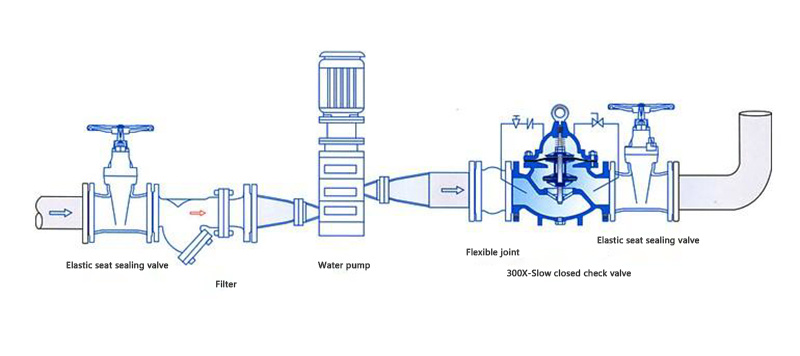

1. One backup, one use installation method should be adopted to avoid the system from not functioning properly after the valve malfunctions;

2. The inlet end of the valve should be equipped with a filter to prevent blockage of magazine particles from causing the valve to malfunction;

3. The closing time of the main valve should not be too slow, otherwise it will cause the water pump and motor to reverse and damage them.

4. Do not open the needle valve too wide.

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.