Y200X-Adjustable pressure reducing valve

- Commodity name: Y200X-Adjustable pressure reducing valve

- Product description

-

PRODUCT INTRODUCTION

An adjustable pressure reducing valve is a water control valve, which consists of a main valve and its attached pipes, needle valves, ball valves, pilot valves, and pressure gauges. Y200X pressure reducing valve is a functional valve that uses the energy of the medium itself to regulate and control pipeline pressure. In terms of transmission, it adopts hydraulic operation, that is, using the water pressure in the pipeline to automatically operate the up and down movement of the main valve disc, control the valve opening, adjust downstream pressure, and maintain downstream pressure at the pressure value set by the pilot valve spring. When the downstream pressure exceeds the set value, the pressure reducing valve automatically closes to ensure that the outlet pressure remains unchanged.

PRODUCT FEATURES

This valve adopts a full channel streamline design, with low fluid resistance and high flow rate. Accurate pressure reduction, stable performance, safe and reliable, easy installation, and long service life. This product is also an ideal product for domestic water supply, fire protection systems, and industrial water supply systems. Welcome to purchase.

STRUCTURAL FORM

The pressure reducing valve consists of a main valve and its attached pipes, needle valves, ball valves, pilot valves, and pressure gauges. Due to the need to connect the pilot valve, needle valve, and pressure gauge to the main valve through a conduit, they are collectively referred to as the conduit control system, as shown in the following figure.

MAIN TECHNICAL PERFORMANCE

Nominal pressure PN 1.0MPa 1.6MPa 2.5MPa Shell experimental pressure 1.5MPa 2.4MPa 3.75MPa Sealing test pressure 1.1MPa 1.76MPa 2.75MPa Maximum inlet pressure 1.0MPa 1.6MPa 2.5MPa Adjustable range of outlet pressure 0.09-0.8MPa 0.10-1.2MPa 0.15-1.6MPa Temperature 0℃-80℃ Applicable Medium Water INSTALLATION AND ADJUSTMENT

1. The best installation method for the main valve is to install it horizontally on the pipeline, with the valve cover facing upwards. Other installation methods can also achieve functional use. Before installation, it is necessary to completely eliminate debris in the pipeline. Pay attention to the water flow identification arrow outside the valve body and follow the direction of installation. After installation, it should be ensured that there is no pipeline stress acting on the valve body and internal components.

2. A gate valve and a continuous filter should be installed in front of the main valve, and a gate valve should also be installed behind the main valve for maintenance.

3. The pipeline system must be thoroughly flushed before water supply.

4. A bypass valve should be installed for important water supply pipelines.

5. Voltage regulation method

5.1 Close the upstream isolation valve (gate valve or butterfly valve), open the downstream isolation valve (gate valve or butterfly valve) for pressure relief, and after the downstream pressure reaches 0MPa, close the downstream isolation valve (gate valve or butterfly valve).

5.2 Tighten the adjusting screw of the pilot valve to the top position and open the needle valve on the main valve to half the position.

Slowly open the upstream isolation valve (gate valve or butterfly valve) until it is fully open.

5.4 Slowly tighten the regulating screw of the pilot valve downwards, and the outlet pressure will gradually increase until the set value is reached, locking the regulating screw.

5.5 When adjusting pressure, do not rush or quickly tighten the adjustment screw. You must adjust it bit by bit according to the state of the pressure gauge behind the valve. If the pressure is adjusted too much, it must be readjusted from the first step, that is, it can only be adjusted from low pressure to high pressure.

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

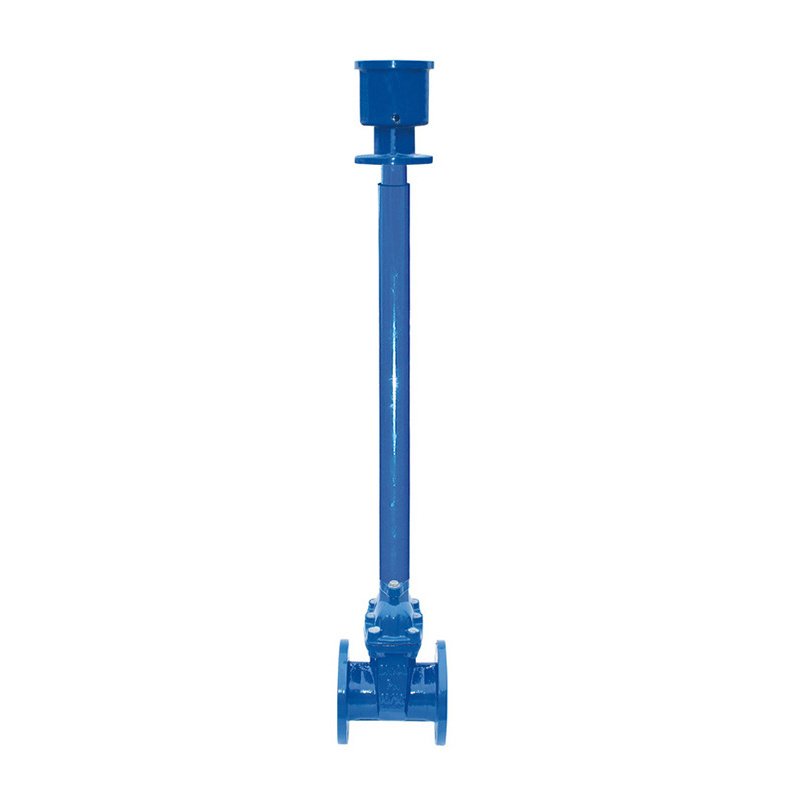

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.