F100X-Remote-controlled float ball valve

- Commodity name: F100X-Remote-controlled float ball valve

- Product description

-

PRODUCT INTRODUCTION

The 100X remote-controlled float valve uses the pressure of the medium itself as the power source to drive the valve to automatically adjust and control the hydraulic control valve of the upper and lower liquid levels in the water tank. Its function is to control the liquid level to reach the upper limit of the water tank, close the control valve, and stop supplying water to the water tank; When the water level reaches the lower limit, the control valve opens and automatically supplies water to the water tank. The height of the upper and lower liquid levels can be adjusted freely within the effective depth range of the water tank. A backup float device is installed below the overflow port of the water tank to prevent water overflow during maintenance or malfunction.

WORKING PRINCIPLE

When the pipeline supplies water from the inlet end, as the needle valve, ball valve, and float valve are normally open, water enters the water tank through the needle valve, control room, ball valve, and float valve. At this time, no pressure is formed in the control room, and the main valve is opened to supply water to the water tank.

When the written height of the water tank rises to the set height, the floating ball rises and closes the floating ball valve, controlling the increase in indoor water pressure, pushing the main valve to close, and the water supply stops. When the water level drops, the float valve reopens, the control room water pressure drops, and the main valve opens again to continue supplying water, maintaining the set height of the liquid level.

MAIN TECHNICAL PARAMETERS

Nominal pressure

(MPa)Shell experimental pressure

(MPa)Sealing test pressure

(MPa)Applicable Medium Medium temperature

(℃)1.0 1.5 1.1 Water 0-80 1.6 2.4 1.76 Water 0-80 2.5 3.75 2.75 Water 0-80 4.0 6.0 4.4 Water 0-80 APPLICATION DESCRIPTION

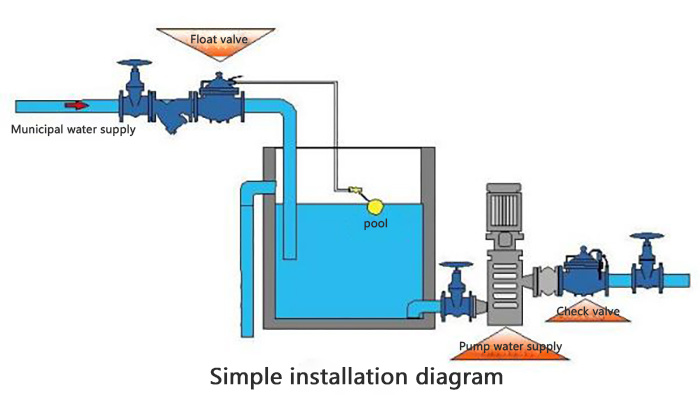

F100X remote-controlled float valve is a hydraulic operated valve that combines multiple functions. To be installed at the inlet of a water tank or elevated water tower, when the water level reaches the set height, the main valve is controlled by a float valve to close the inlet and stop supplying water; When the water level drops, the main valve, together with the float switch, controls the opening of the water inlet to inject water into the water tank, achieving automatic replenishment. Accurate liquid level control, not affected by water pressure interference; The 100X remote-controlled floating ball valve can be installed at any position according to the height and usage space of the water tank. It is easy to maintain, debug, and inspect, with reliable sealing and long service life.

INSTALLATION AND REQUIREMENTS

1. The remote control float valve should be installed on the inlet pipeline of the water tank or water tank, preferably horizontally, with the valve cover facing upwards. The control conduit and float ball should meet the following requirements.

A. The remote control float valve control conduit should be fully fixed on the pool or water tank, and the total length of the control conduit should not exceed 8cm. The center of the float valve should be 1cm away from the water inlet or the inlet pipe should be equipped with a wave suppression device.

There should be anti backflow air holes in the same water tank or above the overflow water level.

Get a Quote

Note: Please leave your email, our professional staff will contact you as soon as possible!

Related Products

Rising stem locking gate valve

The rising stem locking gate valve is a special valve in the fire protection pipe network, which can effectively prevent unnecessary safety production and losses caused by artificial switching or misoperation.

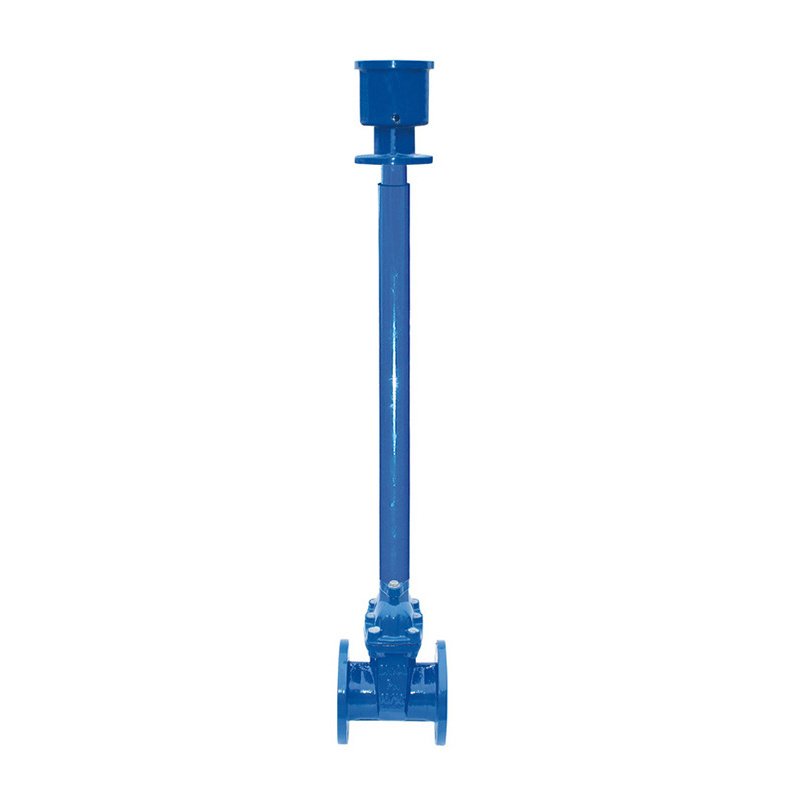

Extension rod gate valve,also called direct buried retractable gate valve is also called the buried soft-sealed gate valve.

Soft seal gate valve with DIN3352 F4

Elastic seat seal gate valve is a new type of valve used for pipeline connection and opening in recent years.

Swing check valve is one kind of one-way check valve to effectively prevent water stop and backflow.